|

TAPED

COMPONENTS |

LOOSE

COMPONENTS |

|

FOR TAPED

COMPONENTS, THE MACHINES CAN BE

MANUAL OR MOTORIZED

|

TO

USE THE LOOSE COMPONENTS MACHINES NEED TO BE MOTORIZED

|

TP6

Cut and bend

machine for axial components.

Several versions available designed for leads with lead diameters from .015 -

.055" (0.4-1.4mm)

ALL

TP6 Spec PDF

ALL

TP6 Spec PDF

TP6 Spec PDF

TP6 Spec PDF

|

|

|

20.OL01

STANDARD

LEAD Ø: 0,4

-1,2

(0.016" - 0.047") |

|

20.OL04

REINFORCED

LEAD Ø: 0,6 – 1,4

(0.024" - 0.055") |

|

|

20.OL06

REDUCED

LEAD Ø: 0,4 – 0,8

(0.016" - 0.031") |

|

20.OL07 / 9 / 10

REDUCED FIX PITCH

LEAD Ø: 0,4 – 0,6

(0.016" - 0.024") |

|

20.OL0130

STRAIGHT CUT |

TP6/M

A

Motor-98

can be connected to the manual TP6 machine.

BODY GUIDES

BODY GUIDES

When it is necessary to bend very close to the body

and the components are not taped with the component body properly centered,

the body guides feed the tape by keeping the component body centered at all

times.

The body guides are used instead of the tape guides.

More Body Guides

info

PDF

More Body Guides

info

PDF

We also offer

Hand

Tools for Cut, Form or Cut & Form.

The following video shows the

TP6/EC machine.

The TP6/EC is the Economy version of the TP6 and works exactly the same way. The only difference is that the TP6 can be motorized and can use the loose

feeder CS10 and the economy machine cannot.

|

TP6/A

TP6 machine with

Motor-98

and

CS10

loose parts feeder. See other

accessories available.

Video of

the CS10.

Do not want to buy a motor and loose parts feeder but still have to prep

loose parts?

We have

tape guides

suitable for loose components that facilitate feeding low volumes

of loose parts:

More info

PDF

More info

PDF

|

|

|

TP6-D

Axial Cut and Bend machine for Axial Components with Delrin Inner

Discs.

The TP6-D cuts & bends axial components as the regular

TP6,

with the difference that this machine has Delrin instead of metal inner

discs so it will not mark the surface of the leads of the components when

it bends them.

This is important when working with very small and delicate components and

for Military applications.

|

|

|

20.OL11 |

Standard machine |

|

20.OL12 |

Reinforced machine |

Minimum cutting

length "B" = 4.6mm and

maximum lead diameter "d" = 0.8mm |

TP6/D-M

A

Motor-98

can be connected to the manual TP6/D machine.

ALL

TP6 Spec PDF

ALL

TP6 Spec PDF

TP6/D Spec PDF

TP6/D Spec PDF

|

TP6/D-A

TP6/D machine with

Motor-98

and

CS10

loose parts feeder.

|

|

|

TP6/97

Cutting and bending machine for axial components with Quick-set-up

This system automatically

adjusts the bending wheels, reducing the

set-up time and making it easier.

This system is available with the some versions of the TP6 machine.

|

|

20.OL01/97

STANDARD

LEAD Ø: 0,4

-1,2

(0.016" - 0.047")

|

|

20.OL04/97

REINFORCED

LEAD Ø: 0,6 – 1,4

(0.024" - 0.055") |

|

20.OL06/97

REDUCED

LEAD Ø: 0,4 – 0,8

(0.016" - 0.031") |

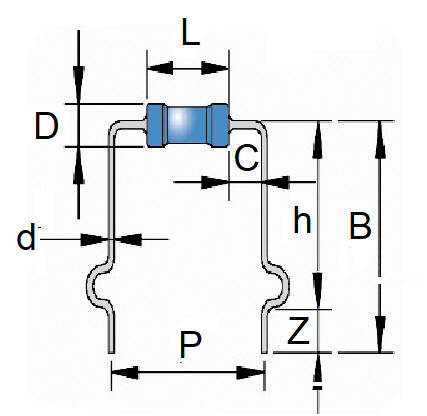

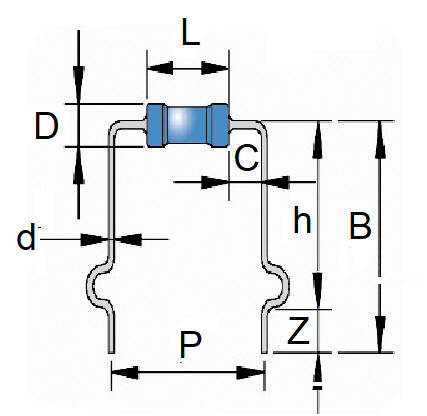

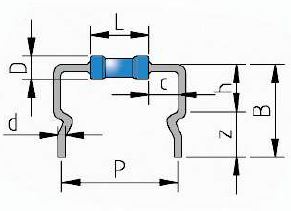

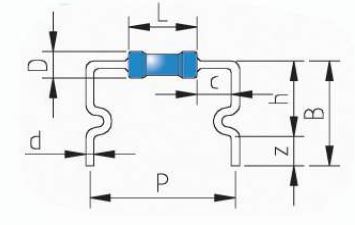

IMPORTANT: the maximum pitch "P" that can be achieved with

the /97 system is 40mm, and the maximum “B” is 10mm

TP6/97-M

A

Motor-98

can be connected to the manual TP6/97 machine.

ALL

TP6 Spec PDF

ALL

TP6 Spec PDF  TP6/97 Specs

PDF

TP6/97 Specs

PDF

|

TP6/97-A

TP6/PR-B machine with

Motor-98

and

CS10

loose parts feeder.

|

|

|

TP6/PR-B

Cutting, bending and forming machine for axial components.

The form obtained

is a Stand-off which keeps the body of the component off the board. No dies

are required.

Large diameter components only:

.039-.055"

(1-1.4mm)

|

|

STANDARD

LEAD

Ø: 1 – 1,3mm

40.OL21 Z=3,1mmm

40.OL31 Z=3,9mm

40.OL24 Z=5mm

|

|

REINFORCED

LEAD Ø: 1 – 1,4mm

40.OL22

Z=3,1mm

40.OL32 Z=3,9mm

40.OL25 Z=5mm

|

|

NOTE:

With the TP6/PR-B it is possible to eliminate the stand-off form

substituting the cutting/forming wheels with "only cutting wheels"

|

TP6/PR-B/M

A

Motor-98

can be connected to the manual TP6/PR-B machine.

TP6/PR-B Specs

PDF

TP6/PR-B Specs

PDF

|

TP6/PR-B/A

TP6/PR-B machine with

Motor-98

and

CS10

loose parts feeder.

|

|

|

TP6/PR-F

Cut, bend and form machine

for axial components.

Three versions are available depending on the lead

diameter of the components:

1. TP6/PR-F/1 -

.019-.035 " (0.5-0.9mm)

2. TP6/PR-F/2 - .031-.039 " (0.8-1mm)

3. TP6/PR-F/3 -

.039-.051 " (1-1.3mm)

Various dies are available for each version.

The

TNS is always supplied with this

machine:

TP6/PR-F Specs

PDF

TP6/PR-F Specs

PDF

|

TP6/PR-F/1

.019-.035 " (0.5-0.9mm)

Most popular

dies: |

|

STAND-OFF LOCK-IN DIES

|

|

STAND-OFF DIES

|

|

STAND-OFF REDUCE PITCH DIES

|

TP6/PR-F/1 Specs

PDF

TP6/PR-F/1 Specs

PDF

|

TP6/PR-F/2

.031-.039 " (0.8-1mm)

Most popular dies: |

|

STAND-OFF LOCK-IN DIES

|

|

STAND-OFF DIES

|

|

STAND-OFF REDUCE PITCH DIES

|

TP6/PR-F/2 Specs

PDF

TP6/PR-F/2 Specs

PDF

|

TP6/PR-F/3

.039-.051 " (1-1.3mm)

Dies available: |

|

STAND-OFF DIE

|

|

STAND-OFF REDUCE

PITCH DIE

|

|

CUT AND BEND DIE

|

TP6/PR-F/3 Specs

PDF

TP6/PR-F/3 Specs

PDF |

TP6/PR-F/A

TP6/PR-F machine with

Motor-98/A

and

CS40

loose parts feeder.

|

|

|

TP6/V

Cut and bend machine for axial components for vertical mount.

Two main versions are available.

The first one for components with lead

diameters .019-.031" (0.5-0.8mm).

The second one for thicker leads

.031-.051" (0.8-1.3mm).

Tooling for different pitches is available.

TP6/V Specs

PDF

TP6/V Specs

PDF

|

Machines for Lead Diameters

0.5-0.8mm - .019-.031" |

|

|

|

80.OL01

P = 2.54mm

(.100")

LEAD Ø: 0,5 - 0,8mm

(0.019" - 0.031") |

| |

80.OL03

P = 3.8mm

(.150")

LEAD Ø: 0,5 - 0,8mm

(0.019" - 0.031") |

|

|

80.OL04

P

= 5.08mm (.200")

LEAD Ø: 0,5 - 0,8mm

(0.019" - 0.031") |

|

80.OL05

P

= 7.62mm (.300")

LEAD Ø: 0,5 - 0,8mm

(0.019" - 0.031") |

|

Machines for Lead Diameters

0.8-1.3mm - .031-.051" |

|

|

|

80.OL21

STANDARD

P = 3.8mm

(.150")

LEAD Ø: 0,8 - 1.3

mm

(0.031 - 0.051") |

|

|

80.OL22

P

= 5.08mm (.200")

LEAD Ø: 0,8 - 1.3

mm

(0.031 - 0.051") |

|

80.OL23

P

= 7.62mm (.300")

LEAD Ø: 0,8 - 1.3

mm

(0.031 - 0.051") |

|

TP6/V-A

TP6/V machine with

Motor

98

and

CS30

loose parts feeder.

|

|

|

TP6/V-PR

Cut, bend and form machine

for axial components for vertical mount.

The standard form will lock the component into the PCB. Handles

components with lead diameters from .019-.031" (0.5-0.8mm).

Pitches .100" (2.54mm) and .200" (5.08mm) are available.

TP6/V-PR Specs PDF

TP6/V-PR Specs PDF

|

TP6/V-PR/A

TP6/V-PR machine with

Motor-98/A

and CS20

loose parts feeder. |

|

|

TP6/S

Cutting, bending and forming

machine for axial components for SMD.

This is a special machine and it is necessary to obtain all dimensions when

ordering.

TP6/S Specs PDF

TP6/S Specs PDF

|

TP6/S/A

TP6/S machine with

Motor-98

and

CS10

loose parts

feeder.

|

|

For Hand Tools to cut and

form

click here

|

|

![]()